Featured Products

Best Sellers

HAVE A SPECIALTY NEED?

We can accommodate. Choose from our specialty categories:

best quality

Our product is 100% Natural Cork.

Free Shipping

We are the direct importer.

professional

Leading the industry in cork since 1921.

Made in Usa

Proudly Made in USA.

Our Clients Say

Did you know that cork is…

FOR COMMERCIAL & INDUSTRIAL APPLICATIONS

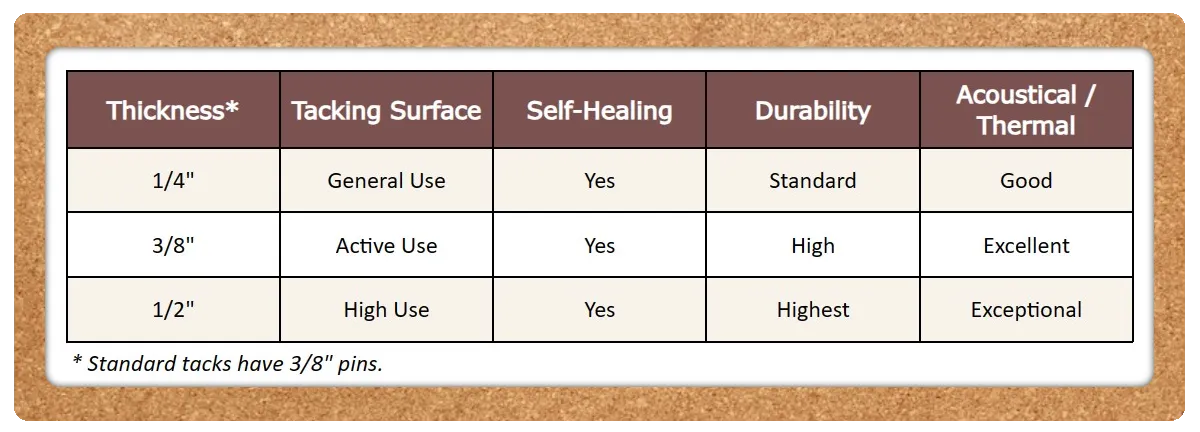

Cork Rolls & Sheets from 1/32″ (.7938″) Thickness

- Widths to 72″

- Adhesive (PSA) Backing

- Rolls Cut to Spools

- Fire Rated Materials

Custom Produced to your Specifications

CLICK FOR DETAILSMember of Cork Institute of America

The Cork Institute of America is a member-supported organization dedicated to promoting cork and cork products in North America. Our mission includes research, education and communications to help advance the use of cork in both consumer and commercial applications. Our members include importers, converters and manufacturers of cork and cork products.

If you are a producer of cork products, we hope you will join our growing organization. If you are a user of cork please utilize our website to locate reliable, quality sources and add your name to our mailing list to receive informational updates about our industry.

- Call us:800-663-1921

- Email us:corkman@mantoncork.com

Need help? Please Contact Us

How Can We

Help You Today?

- Call us:800-663-1921

- Email us:corkman@mantoncork.com

Hold on - SUPER - PATIENT - HELPFUL - KNOWLEDGEABLE - CARING - PROFESSIONAL - SINCERE - PROMPT - PATIENT @ CARING - The order done right AND shipped - arriving quickly AND in great shape - MANTON - KRISTIN - TEE-RIFF-ICK! And NOT the "ick" above, but ALL TERRIFIC!!!!!!! Sincerely and with APPRECIATION !!!! .......written with pleasure AND HONESTY!!!!

Just finished installing my new cork quilting design/everything wall. And… I accomplished this task all by myself. That may not sound amazing, but I am a 70+ year old Grandma who loves to quilt love blankies for my family and friends. Your directions (and one quick phone call) made this project a pleasant experience. And I did it! Love my new wall!!

Thank you so much Manton Cork employees! You helped me get our bulletin board cork here quickly — you have no idea how proud our students will be to have even more work displayed! I will be highly recommending your company and letting my fellow teachers know how great your product is and how outstanding your customer service is!

Hi Jerry & Kristen, Just wanted to thank-you both for all your help on this project. The 50-4’ x 6’ and 16-2’ x 3’ cork boards came out perfect. Lot of work though.

BRAVO!!!!! You guys are awesome!!. Looking forward to this product solving our cork board issues. Thank you for the Five Star Service. Thank you for being honest about the ship date too. :)